Copyright © 2020 - 2024 All rights reserved

Patriot Laser Engraving® •Vine Grove, Kentucky • U.S.A.

(502) 822-6136

A BRIEF EXPLANATION OF WHAT LASER ENGRAVING IS ABOUT

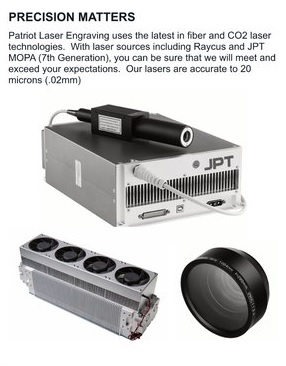

Fiber laser engraving, a state-of-the-art technology, harnesses the power of high-energy laser beams to engrave, mark, or etch various materials with outstanding precision and accuracy. This modern technique has transformed how we personalize items ranging from jewelry and electronics to medical instruments and automotive components.

The core of fiber laser technology lies in its ability to generate a concentrated beam of light from a fiber optic source. This beam is intensely focused and can be directed with meticulous control onto the material's surface, vaporizing it to leave a permanent, high-quality mark. The precise nature of this beam allows for the creation of detailed designs, fine text, and complex patterns on a diverse array of materials, including metals, plastics, ceramics, and glass.

Fiber lasers are especially favored for tasks that require high durability and longevity in the markings, making them ideal for industrial applications in aerospace, automotive, and manufacturing sectors. They are also popular for creating personalized gifts and promotional items due to their ability to produce clear, detailed engravings on both metal and non-metal surfaces.

In addition to fiber lasers, other types of laser technologies include CO2 lasers and UV lasers. CO2 lasers, which use a gas mixture to generate laser beams, are particularly effective for engraving on non-metal materials such as wood, leather, and acrylic. They are known for their smooth finishes and are commonly used in the signage and decorative industries.

UV lasers, on the other hand, offer a different approach by utilizing ultraviolet light to achieve extremely fine and precise markings. This type of laser is particularly useful for delicate applications such as engraving on glass and certain plastics, where other lasers might cause damage due to higher heat output.

Overall, the field of laser engraving is marked by continuous advancements, providing ever-improving tools for creating durable and aesthetically pleasing customizations. Whether for industrial use or personalization, laser technologies like fiber, CO2, and UV lasers offer a versatile and reliable solution for a wide range of engraving needs.

ANNEALING

Laser annealing is a process that uses high-energy laser beams to heat and alter the microstructure of a material's surface, without melting or damaging the material itself.

This process is typically used to create a durable and high-quality surface finish on metal materials, such as stainless steel, titanium, and aluminum.

During laser annealing, the laser beam is directed at the material's surface, which causes localized heating and cooling.

This process changes the microstructure of the material's surface, creating a uniform and durable surface finish that is resistant to wear, corrosion, and other forms of damage.

Laser annealing is often used in the manufacturing of medical devices, aerospace components, and automotive parts, where durability and high-quality surface finishes are critical.

One of the primary benefits of laser annealing is its ability to produce high-quality surface finishes with very precise control over the process.

The laser beam can be precisely directed to heat specific areas of the material's surface, which allows for the creation of intricate designs, patterns, and logos.

Additionally, laser annealing is a non-contact process, which minimizes the risk of damaging the material and ensures that the surface finish is consistent and uniform.

ETCHING

Laser etching is a process that uses high-powered laser beams to remove a very thin layer of material from the surface of a material, creating a precise and detailed etching.

This process is typically used to create intricate designs, patterns, and logos on a wide range of materials, including metal, plastic, and glass.

During laser etching, the laser beam is precisely controlled to create a very fine and precise etching, with depths ranging from a few microns to several millimeters.

Laser etching is often used in the manufacturing of electronic devices, jewelry, and other high-precision applications, where intricate and precise markings are critical.

One of the primary benefits of laser etching is its ability to produce high-quality, precise, and permanent etchings with excellent clarity and detail.

Laser etching can create etchings with a precision and level of detail that is unmatched by traditional etching methods.

Additionally, laser etching is a non-contact process, which minimizes the risk of damaging the material and ensures that the etching is consistent and uniform.

Laser etching is an excellent choice for creating intricate and precise etchings on a wide range of materials.

DEEP ENGRAVING

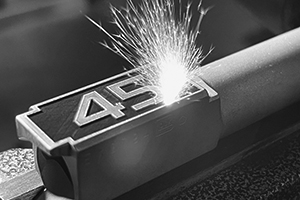

Laser deep engraving is a process that uses high-powered laser beams to remove material from the surface of a material, creating a deep and precise engraving.

This process is typically used to engrave complex designs, logos, and text onto a wide range of materials, including metal, plastic, and wood.

During laser deep engraving, the laser beam is directed at the material's surface, which causes localized heating and vaporization of the material.

The laser beam is precisely controlled to create a deep and precise engraving, with a depth of up to several millimeters.

Laser deep engraving is often used in the manufacturing of firearms, aerospace components, and automotive parts, where durability and precise markings are critical.

One of the primary benefits of laser deep engraving is its ability to produce deep, precise, and permanent engravings with excellent clarity and detail.

Laser deep engraving can create engravings with a depth and clarity that is unmatched by traditional engraving methods.

Additionally, laser deep engraving is a non-contact process, which minimizes the risk of damaging the material and ensures that the engraving is consistent and uniform.

Laser deep engraving is an excellent choice for creating durable and high-quality engravings on a wide range of materials.